Squeegee blades are one of the most important parts on your floor scrubber. Without a high quality and properly maintained squeegee, you can be left with wet and streaky floors. This impacts the appearance and safety of your floors. Here are some tips for choosing the correct squeegee, as well as how to maintain it.

For more information, speak with your KSS consultant or request a consultation online here.

Squeegee Blades Overview

What is a squeegee blade? Other than being a funny word, the squeegee is arguably one of the most important components of a floor scrubber. In the simplest terms, a squeegee is a piece of rubber, urethane, Linard® or Linatex® that attaches to the back and/or sides of a floor scrubber or sweeper-scrubber. It funnels water so the vacuum fan can pick up the liquid as the floor cleaning machine passes over it. The combination of the squeegee assembly, squeegee blades and vacuum fan allows for optimal water pick-up.

The squeegee is a critical component of the machine’s water management system, which leaves floors clean, and even more importantly, dry and safe. This helps to prevent slip-and-fall accidents, one of the most frequent types of worker compensation claims, according to the EHS Daily Advisor.

If your squeegees are not properly maintained, your scrubber may leave behind streaks, debris or water. This results in rework and wasted time, which costs you extra money.

EVERY 30 MINUTES OF EXTRA CLEANING = $198 EXTRA LABOR COSTS PER MONTH, OR $2,370 ANNUALLY*

Squeegee Materials

There are multiple materials that floor cleaning squeegees can be made of, such as rubber and urethane. Each material has qualities that make it ideal for certain types of floors or environments.

Gum rubber squeegees are the lowest cost, which helps you save money on replacements. These squeegees are slightly stiffer. They are recommended for smooth and even indoor floors. Gum rubber is not chemical resistant.

Urethane squeegees are chemical resistant, meaning they are ideal for cleaning organic and petroleum-based oils.

Linatex® is a premium squeegee material and comes standard on most Tennant equipment. The proprietary material offers outstanding strength, resilience and resistance for long-lasting performance.

Linatex is ideal for wet applications when paired with a Linard® squeegee for the front blade.

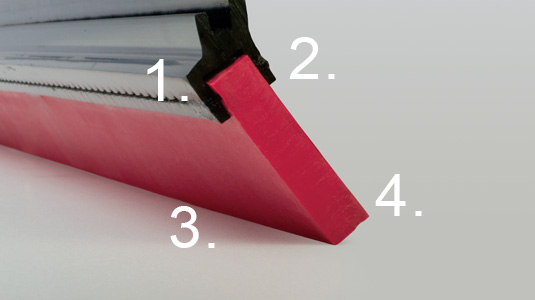

By rotating the squeegee, you can clean with all four sides of it – increasing the life of the squeegee.

Floor scrubbers have squeegees on the back, and sometimes sides, to help funnel water and cleaning solution so the vacuum fan can suck them up as it cleans, leaving your floor clean and dry.

When a squeegee is worn halfway through, rotate it to a new side to maintain optimal performance.

Squeegee blade Replacement and Maintenance

While squeegees may be one of the most commonly replaced parts on your floor cleaning equipment, there are many things you can do to keep them in optimal condition for as long as possible.

- Rotate squeegees for increased life. By rotating which side of the squeegee is on the floor, you can get longer use out of a single squeegee. Squeegee wear depends on the material of the squeegee and the type and condition of the floor. Inspect the condition of your squeegee blades daily. Rotate or replace the blade when it is worn halfway through.

- Replace squeegees before they become ineffective. When you begin to see wear and tear on an edge of your squeegee, rotate it in a timely manner. Once cleaning on the 4th edge, have a replacement ready to go. This way you’re always cleaning with a highly performing squeegee and not sacrificing cleanliness and safety.

- Purchase OEM squeegees for optimal performance. Look-alike or third-party squeegees are not specifically designed for your cleaning machine. They may not provide the quality of cleaning you expect.

While the squeegees may look the same, don’t be fooled by lower priced parts. You will spend more money in the long run replacing poor quality squeegees.

Ensure there is even pressure across the entire squeegee. A properly positioned squeegee has even pressure from tip to tip. It is set on the floor at an angle where the inside edge of the squeegee blade is scraping across the floor for optimal water pick-up. If there is too much pressure, the squeegee can get smashed down and will not pick up water properly.

How to resolve common squeegee issues:

- Squeegee is not picking up water in the center. Adjustments to the amount of pressure on the squeegee can be made to ensure there is equal distribution across the entire length. Doing so will prevent the center of the squeegee from being higher than the tips. Review your operator manual to understand how to best adjust the squeegees on your machine.

- Squeegee is not picking up water on the edges. Similar to the example above, there may be adjustments that need to be made to ensure the squeegee is dragging across the floor at the correct angle. Review your operator manual to understand how to best adjust the squeegees on your machine.

- Streaks are being left on the floor. In this case, it’s likely your squeegee has dirt or debris built up on it. This will cause the squeegee to inconsistently drag across the floor. To resolve, raise your squeegee assembly and wipe the length of your squeegees with a clean rag or towel to remove the debris.

By choosing the right squeegees for your environment and properly maintaining them, you will save money and time in replacement costs and rework.

Need help choosing the right squeegee for your floor type?

Download the squeegee guide to ensure you’ve got the correct one!

For more information, fill out the contact form online or call and talk to a KSS representative today at 1.800.638.4191.

Source: “Squeegee Blades 101” by Tennant Company

*Based on a 7-day cleaning cycle with labor costs at $13 per hour